Electric power utilities consistently face the challenges of unplanned downtime and the threats it poses to operational continuity, financial stability, and stakeholder confidence. As infrastructures age, the underlying issue in equipment failure often lies in the gradual deterioration of critical electrical connections—terminals, joints, and connectors—attributed to factors such as corrosion, loose fittings, and increased resistance. These issues, if left unaddressed, can lead to excessive heat generation, electrical fires, and disruptive power outages.

The C8 Thermal Imaging Solution

While power utilities have traditionally used handheld thermal imaging devices to monitor their assets, implementing remote and real-time monitoring solutions is imperative for enabling early detection of potential issues and safeguarding operations against unwanted downtimes.

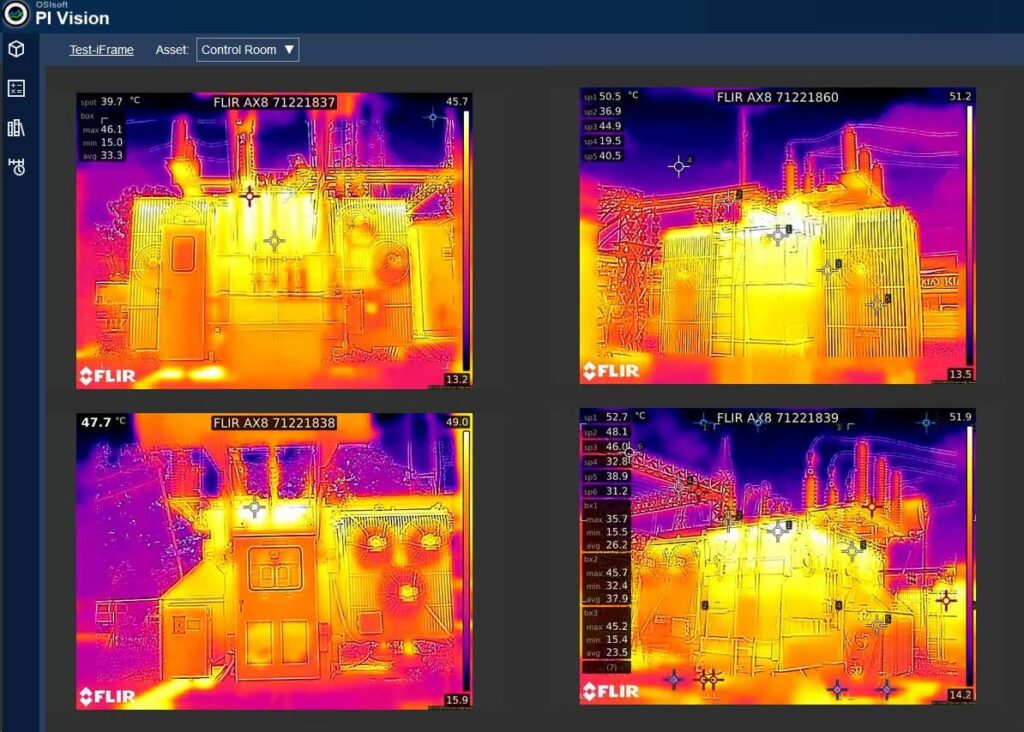

Calibr8’s C8 Thermal Imaging solution uses advanced thermal cameras equipped with Pan, Tilt, and Zoom capabilities for non-invasive and remote monitoring of critical assets, offering a comprehensive wide view of monitored assets or areas of concern.

This advanced solution is also integrated into the PI System and can send smart notifications to provide critical insights into temperature hotspots, offer customized visualization of temperature parameters, and advanced analysis from the thermal camera installed on-site, giving operators a comprehensive view and understanding of the condition of their critical assets.

Here are some ways you can use the C8 Thermal Imaging Solution to elevate your asset monitoring and maintenance practices:

Transformer Health Monitoring

C8 Thermal imaging can be used to monitor the temperature of transformer components. Early detection of hotspots in transformers can indicate issues such as winding insulation problems or loose connections. When the thermal data is integrated into the PI system, it allows for real-time monitoring and trend analysis. The PI system can trigger alerts or notifications when temperatures exceed predefined thresholds, allowing for a swift response to potential issues.

Substation Monitoring

In substations, C8 Thermal Imaging can be applied to monitor critical equipment such as circuit breakers, busbars, and disconnect switches. Anomalies in temperature can signal impending failures or deteriorating conditions. Integrating this information into the PI system facilitates alarms, centralized monitoring and analysis, and supports decision-making for maintenance actions.

Switchgear Inspection

C8 Thermal Imaging is also valuable for inspecting switchgear components in power distribution systems. Changes in temperature patterns may indicate loose connections, overloaded circuits, or faulty components. Its integration with the PI System provides a centralized platform for monitoring switchgear health and scheduling maintenance activities based on actual conditions.

Distribution Transformer Fleet Management

Power utilities often manage a large fleet of distribution transformers. C8 Thermal Imaging can be used to assess the health of these transformers remotely. Integration with the PI system allows for continuous monitoring of multiple transformers, helping utilities prioritize maintenance based on the condition of each unit, reducing downtime, and optimizing resources.

Energy Efficiency Optimization

C8 Thermal Imaging can also be employed to identify areas of excess heat in power distribution systems, indicating inefficiencies or overloads. By integrating thermal data into the PI system alongside energy consumption information, operators can optimize the system for better efficiency, reduce energy losses, and lower operational costs.

Remote Monitoring of Remote Assets

In areas with limited accessibility, such as remote substations or off-grid installations, thermal imaging provides a means to remotely monitor critical assets. The integration with the PI system enables operators to receive real-time data and alerts, allowing for timely responses to emerging issues without the need for physical inspection.

KEY ADVANTAGES

- Remote monitoring and real-time insights into temperatures of critical assets.

- Immediate detection of anomalies through alarms and notifications.

- Identification of degradation trends with long-term data storage.

- Generation of reports and customized, real-time visualizations of thermal data trends, anomalies, and maintenance activities.

- Integration with other sensors.

Conclusion

The C8 Thermal Imaging solution for power transmission and distribution enables a more proactive, data-driven approach to asset monitoring and maintenance. This can result in improved reliability, increased safety, and optimized operational efficiency for the entire power infrastructure. By staying ahead of potential failures, operators can mitigate risks, ensure a reliable power supply for customers, and preserve their trust in the system.

If you’re looking to future-proof your operations and systems, book a demo with us to find out more about Calibr8 Systems.